Polyvinylchloride, whose main component is polyvinyl chloride, is brightly colored, corrosion-resistant, strong and durable. Due to the addition of some toxic auxiliary materials such as plasticizers and anti-aging agents during the manufacturing process to enhance its heat resistance, toughness, ductility, etc., Therefore, its products generally do not store food and medicine. It is a synthetic material that is loved, popular and widely used in the world today. Its global usage ranks second among various synthetic materials. According to statistics, in 1995 alone, the production volume of PVC in Europe was about 5 million tons, while its consumption was 5.3 million tons. In Germany, the production and consumption of PVC averages 1.4 million tons. PVC is being produced and applied worldwide at a growth rate of 4%. In recent years, the growth rate of PVC in Southeast Asia has been particularly significant, thanks to the urgent need for infrastructure construction in Southeast Asian countries. Among the materials that can produce three-dimensional surface films, PVC is a suitable material. PVC (polyvinyl chloride), the simple structural formula of its monomer is CH2=CHCl.

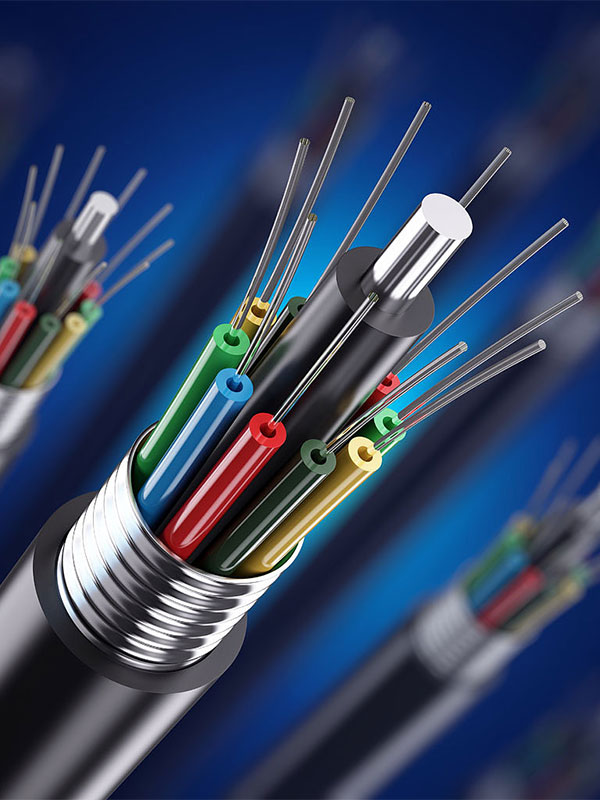

PVC material has a wide range of uses, with good processing performance, low manufacturing cost, corrosion resistance, insulation and other good features. It is mainly used to make: Previn PVC cards; PVC OEM; PVC iron wire; PVC curtains; PVC plastic-coated welded mesh; PVC foam board, PVC ceiling, PVC water pipes, PVC skirting, etc. as well as threading pipes, cable insulation, plastic doors and windows, plastic bags, etc. PVC products can be seen everywhere in our daily lives. PVC is used to make various imitation leathers for luggage bags, sports products such as basketballs, footballs and rugby balls, etc. It can also be used to make belts for uniforms and special protective equipment.